Have you ever come across the torn opening defect on the hose burst protection sleeve?

I assume many of you met them before.

Some of you may have tried to tear the opening when doing a quality test.

> > > >

When you feel bored or anxious, the action on the right would be a good way for you to relax.

However, to a textile protection sheath, the raw edge must be a quality defect absolutely. The sheaths will be completely destroyed by being kept pulling out the loose weft thread.

Then let’s go back to the torn opening defect showed above. Why did the opening break?

How about the raw edge on below GIF?

OUT THE OVERLOCKING SEAMING

Both the defects of the broken opening and raw edge are caused by it.

▶ Why the Overlocking Seaming is important?

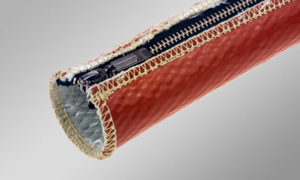

Overlocking Seaming, just as its name implies, is to strengthen and prevent the fraying of an edge of cloth by oversewing it. It helps to make the protection sheath stronger to avoid any potential risk during the lining process. This construction is also a must on safety belts for the firefighters and skydiving straps.

The sleeve with overlocking seaming can’t be torn or pulled out the thread easily even without heat cutting or heat sealed. Overlocking Seaming is a plus construction for the hose burst protection sleeve, also called hose abrasion protection sleeve.

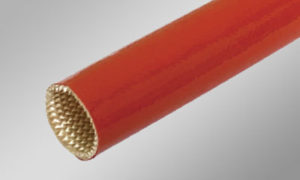

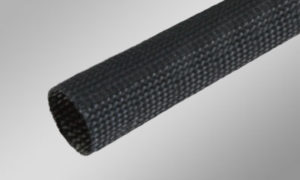

Let’s see Hantai’s textile protection sleeve with overlocking seaming.

▶ Is the Overlocking Seaming common in the hose protection sheath?

It is time-and-labour consuming to overlock the seam during the bulk production, which increases the cost. Some manufacturers taking cost as the priority will skip the process to save the cost. Although the product price is lower, the product quality and protection are degraded in the meantime, which may cause a potential risk on the protection.

▶ Hantai, as a professional and thoughtful manufacturer

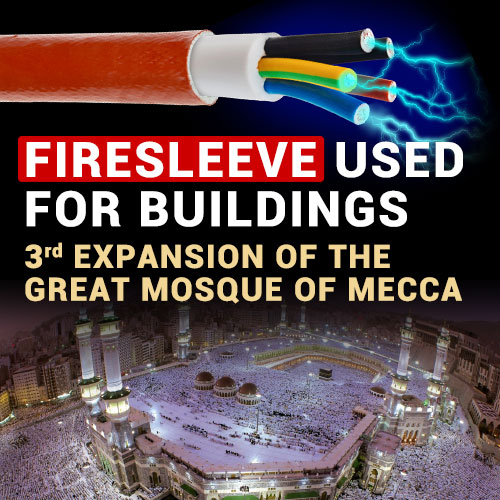

Hantai always take quality as the priority and consider more aspects for our customers, no matter for the product quality or function. Our textile protection sleeve has been accepted by MSHA (Mine Safety & Health Administration). It is an endorsement of our protection sleeve.

Besides the closed sleeve, protection sheaths with Velcro closure are available.

If you have any query on the abrasion protection or thermal insulation to your hose, cable and equipment, please feel free to contact us at any time. We will offer you solutions ASAP.