In latest news report, we learn that California (USA) has been threatened by wildfire for weeks. But there’s a funnyguy answering about actions to containthe wildfire that “It’ll start getting cooler. You just watch!” People in the universe except him know that fire will not get extinguished shortly if we don’t take proper and timely actions. Let’s pray that God bless people in California and the surroundings.

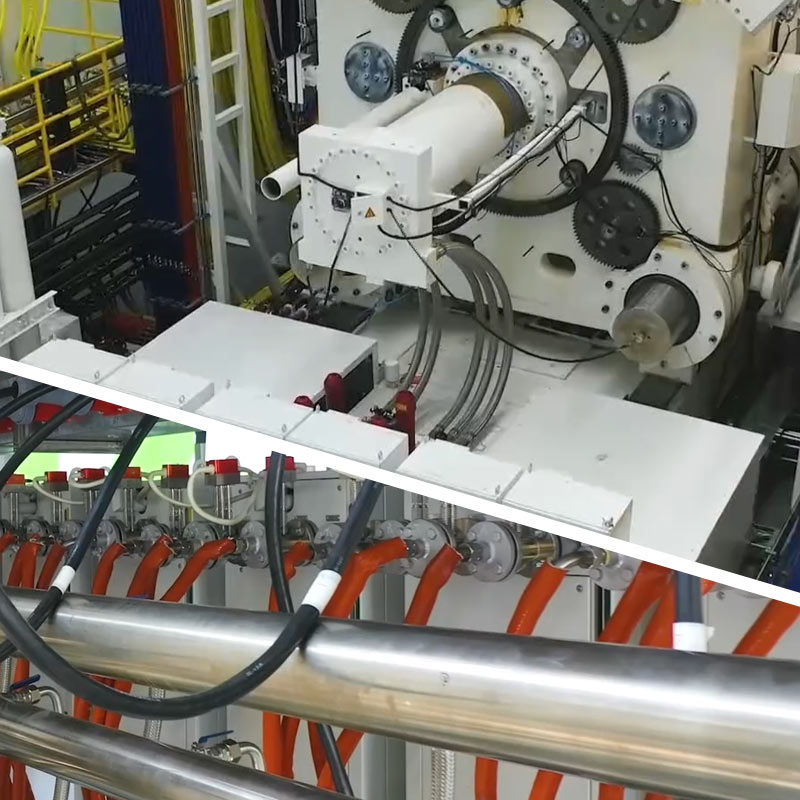

Speaking of fire threat, there is a place with potentially frequent fire hazards and accidents – mining. According to the International Labor Organization (ILO), while mining employs around 1% of the global labor force, it generates 8% of fatal accidents and fires. Thus the safety of objects is always concerned a lot by each mine, especially the fire resistance properties of objects. Nylon sleeve, as a widely used abrasion resistant product protecting hoses and wires in mines, its safety for use during fire outbreak is highly concerned. Then how to evaluate its safety?

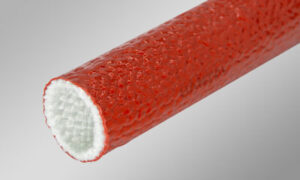

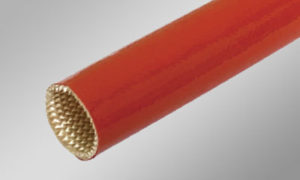

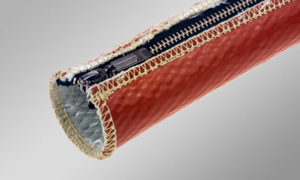

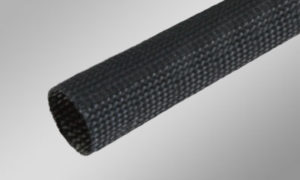

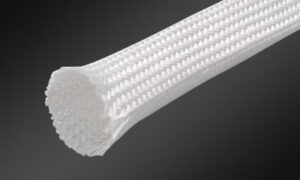

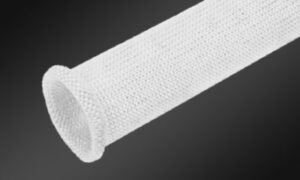

Now, go back to our question – how to evaluate the safety of the nylon sleeve? Yes, maybe you have got it, making it meet MSHA standard is one choice. Then what’s the requirement? There are specific requests regarding hose test under MSHA. In short, the key point is fire resistant. We, Hantai,are proud of obtaining MSHA acceptance for nylon sleeve recently. Hantai nylon sleeve is an economical yet durable solution to protect hoses for a longer life, particularly under sever abrasion and degradation conditions, and offers minimized burst and containment protection to users and asset at the same time.

To make it easy to understand the test under MSHA requirement, let’s review the test procedure:After conditioning, samples are exposed to 60 seconds of ignition by a Bunsen burner flame in still air, then followed by monitoring for pass/fail criteria under 300 feet/min. airflow.

Please refer to Hantai nylon sleeve test result:

Yes, as you can see, excellent performance. Hantai nylon sleeve flame time is ZERO, though max acceptance is 60 seconds. And it is zero for afterglow time too (maximum time acceptance is 180 seconds). It is in higher level than MSHA requirements. If the flame time is longer, it is more dangerous for using, same as the afterglow time. What does it mean? When touched with instantaneous flames or sparkle, Hantai nylon sleeve won’t be burned. It will protect objects well and won’t speed up the fire spreading, thus to avoid some fire hazards. It is a good choice for you.

However, getting access to MSHA acceptance list does not mean everything. As what we said before, a safe product does not really come from a certification, it is always from someone reliable and full of responsibility for human health and property safety. We are proud to say that Hantai was, is and will be on the way to perform responsibility and proficiency! When you are going to buy nylon sleeve, just remember, Hantai products concern more about your safety and health.