Even though the Covid-19 Pandemic prevails worldwide in recent years, Hantai has managed to overcome difficulties and challenges to keep her pace of expansion and upgrading facilities and machines, providing a more timely and stable supply of firesleeve with premium quality to worldwide customers.

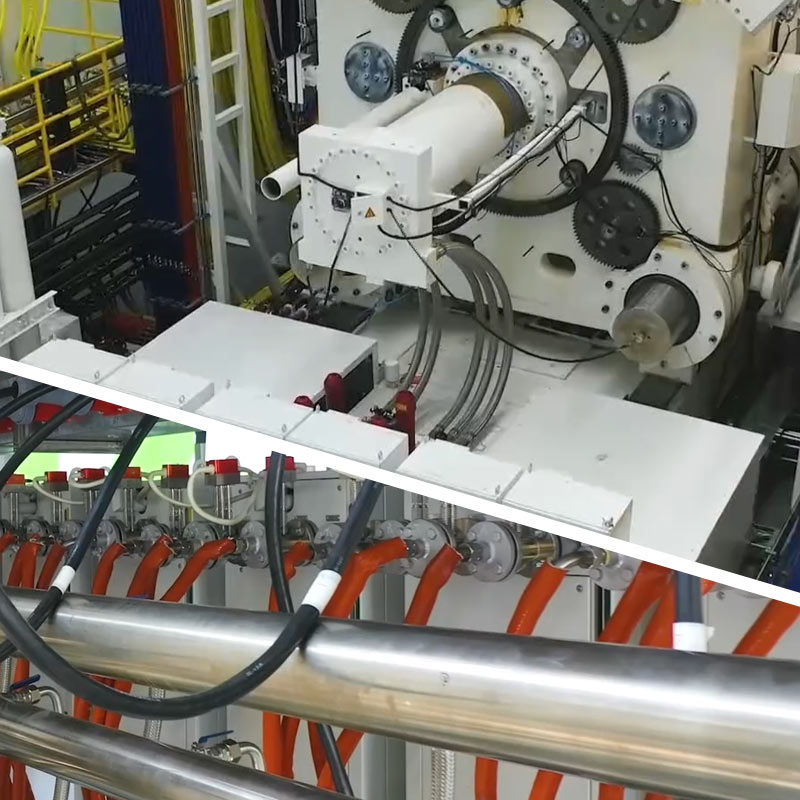

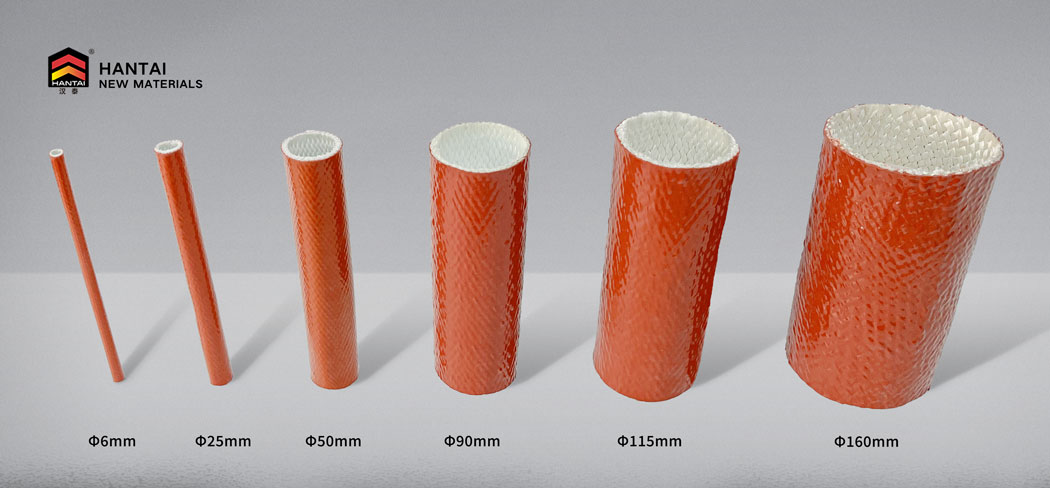

Hantai has brought in new braiding sleeving machines for bigger sizes, marking Hantai as the first factory equipped with proper machines to produce fire sleeve with ID up to 160mm in China.

The proper machine is the foundation to produce qualified products!

However, as a professional manufacturer, we know some factories, which have just a few / limited production lines or want to “save cost”, are using up the “trick” of braiding sleeves to produce Firesleeve with a “bigger” ID.

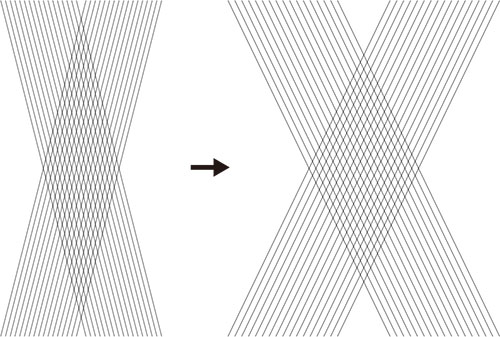

This trick lies in the braiding angles of fiberglass sleeve.

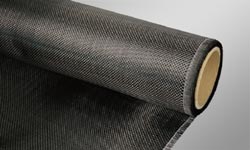

Proper braiding angle is guaranteed for qualified sleeving products (including fiberglass sleeve, basalt fiber sleeve, silica fiber sleeve, etc.) to be woven tightly enough for delivering good performance, while those with too small braiding angles could result in bad quality and poor performance. Please refer to the following for more info.

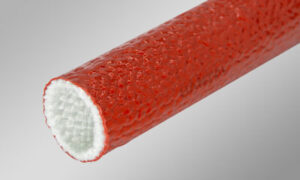

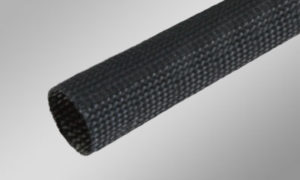

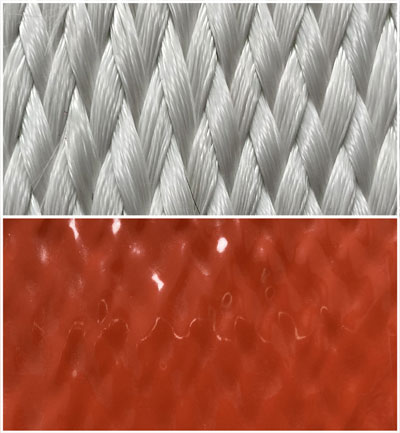

Proper weaving machines with braiding angles of 45°, like HANTAI fire sleeve.

1) Tightly woven sleeves, slower braiding speed.

— sufficient materials, good thermal insulation

2) Good and even coating

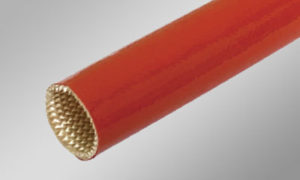

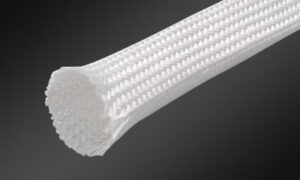

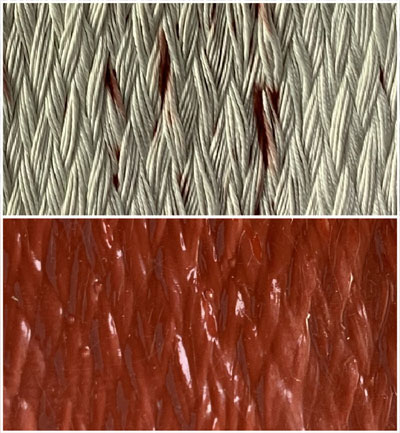

Improper weaving machines with small braiding angles, like some fire sleeve.

1) Loosely woven sleeves, faster braiding speed

— Less materials, poorer thermal insulation

2) Uneven coating, and coating easily penetrates inside the sleeve

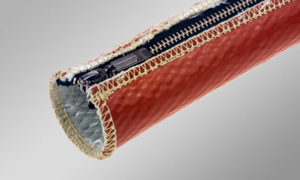

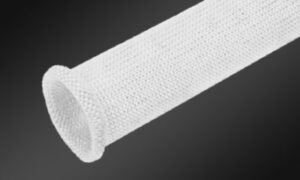

What’s more, a smaller braiding angle would allow bigger expansion. Some manufacturers even use it to produce larger fire sleeve by intentionally enlarging the sleeve ID, for example, they may expand the sleeve ID100mm to 110mm, and then do the coating, which comes out as an ID110mm firesleeve.

A sleeve with a small diameter is intentionally enlarged to a bigger diameter, resulting in an even more loose braiding structure and thinner wall thickness.

As a result, this kind of firesleeve could have much more severe problems of coating penetration, uneven coating, poorer thermal insulation, and nonuniform diameter along the length.

Those factories are producing poor quality firesleeve to “save cost”!

Hantai insists in producing fire sleeve with proper machines and with proper braiding angles, so as to guarantee qualified firesleeve, though it means a bigger cost. We believe in “Qualified Product First”.

With these new braiding machines, Hantai now is also able to produce bigger sizes for fiberglass sleeve, basalt fiber sleeve, silica fiber sleeve, and basalt fiber firesleeve etc.

Welcome to contact Hantai sales team to know more info about

Hantai thermal insulation sleeving products.