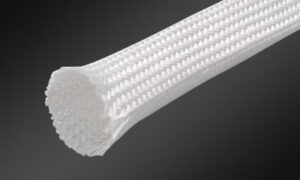

Basalt Fiber Firesleeve

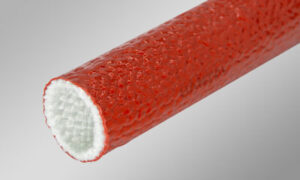

• Materials: Basalt Fiber, Silicone Rubber

• Inner Substrate Temperature Resistance: 760℃

• Outer Coating Working Temperature: Continuous working at 500°F (260°C), peaks at 3000°F (1650°C)

• Size Range: Φ6mm – Φ160mm

Basalt Fiber Firesleeve – the ultimate solution for high temperature protection with a focus on environmental sustainability.

DESCRIPTION

Hantai Basalt Fiber Firesleeve, designed to offer exceptional high-temperature resistance and environmental protection. This innovative product is engineered to safeguard against heat-related hazards while ensuring sustainability in various industries.

High Temperature Resistance

Hantai Basalt Fiber Fire sleeve is specifically woven from high-quality basalt fibers known for their exceptional thermal properties. With an outstanding melting point and stability, this sleeve effectively withstands extreme temperatures, ensuring reliable insulation and protection in demanding environments. It acts as a barrier, preventing direct exposure to heat and reducing the risk of fires or thermal damage.

Enhanced Safety Features

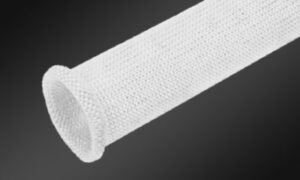

The basalt fiber composition provides excellent thermal insulation, keeping equipment and personnel safe from potential risks associated with excessive heat exposure. By effectively dissipating heat and redirecting it away from critical components, our fire sleeve adds an extra layer of protection to sensitive machinery, cables, wires, and pipes.

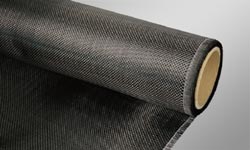

Environmental Sustainability

We are committed to environmental responsibility, and the use of basalt fibers in the production of the firesleeve emphasizes our dedication to sustainability. Unlike traditional materials, basalt fibers are derived from natural volcanic rock and do not require harmful additives or chemicals during manufacturing. Additionally, the manufacturing process itself consumes significantly less energy and produces fewer emissions compared to other synthetic fibers.

CHARACTERISTICS – Basalt Fiber Fire sleeve

| PRODUCT |

Basalt Fiber Firesleeve / Basalt Fiber Fire Sleeve |

| HANTAI PART NO# | HT51S-**S (**refers to the inner diameter=ID) |

| MATERIALS | Basalt Fiber, Silicone Resin |

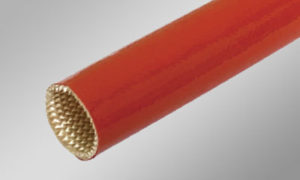

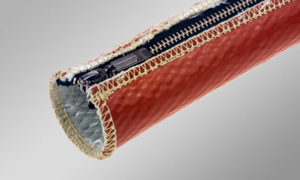

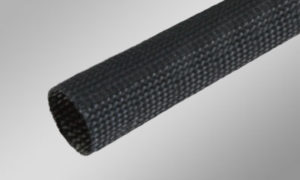

| CONSTRUCTION | Braided |

| SIZE RANGE | 1/4″ (6mm) – 6 3/8″ (160mm) |

| INNER SUBSTRATE TEMPERATURE RESISTANCE | 760℃ |

| OUTER COATING WORKING TEMPERATURE | 260℃ Continously, 1650℃ for Max Short Term Exposure |

| COLOR OPTIONS | Standard: Iron Oxide Red; Others: Blue, Black, Yellow, Grey, etc. on request |

| ROLL LENGTH | 100 meters / roll |

| AVAILABLE OPTIONS | Special bulk packaging (maximize productivity/minimize waste) Pre-cut short length |

| TYPICAL INDUSTRIES | Protecting hydraulic hoses, cables, wiring, used in metallurgy, steel mills, glass work, marine industry, petrochemical industry etc. |

Applications

Hantai Basalt Fiber Firesleeve finds extensive application across various industries, including Aviation, Military, Metallurgy, Automobile, Electronics, Shipbuildings, etc. It is suitable for protecting electrical wiring, hydraulic hoses, fuel lines, and other critical components that are susceptible to high-temperature environments. Featuring excellent flexibility and durability, this sleeve is easy to install and can be customized to meet specific requirements.

Conclusion

With its outstanding high temperature resistance, enhanced safety features, environmental sustainability, and versatile applications, Hantai Basalt Fiber Firesleeve is the ideal solution for industries seeking reliable protection against heat-related hazards. Invest in our innovative product today and ensure the utmost safety while contributing to a sustainable future.