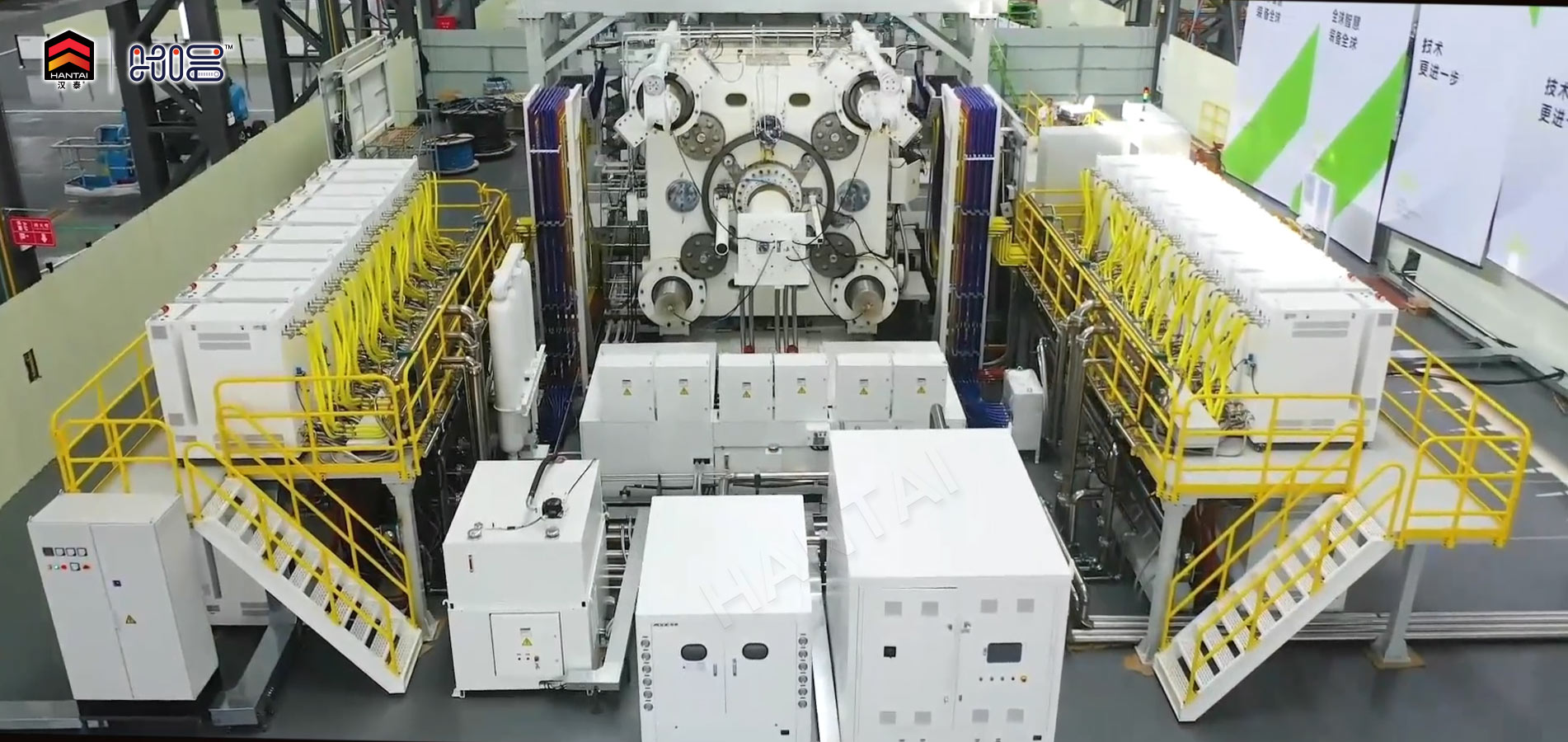

The Critical Role of Die-Casting Islands

As an integrated production system, the die-casting island injects molten metal into molds to form precision castings. Fire Sleeve-protected hydraulic systems enable continuous operation under extreme conditions, particularly crucial for NEV megacastings requiring 9,000+ ton clamping force.

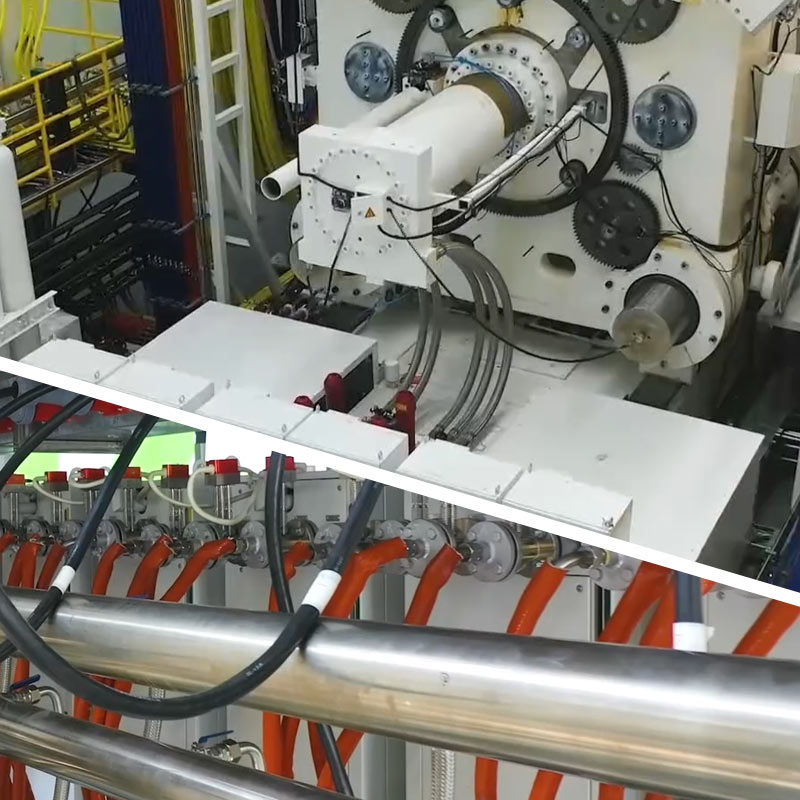

High-Temperature Risks in Fluid Pipelines

Key pipelines within die-casting islands require Fire Sleeve thermal barriers to combat:

- Surface temperatures exceeding 800°C

- Instantaneous spikes to 1,650°C from molten aluminum

- Hydraulic hose hardening (70% hardness increase at 260°C/500h)

Hantai Fire Sleeve: Engineered for Industrial Extremes

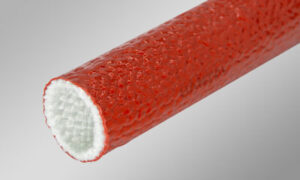

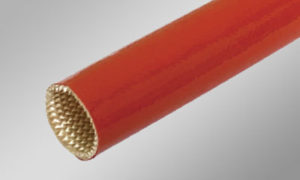

Material Science Innovation

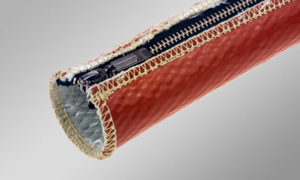

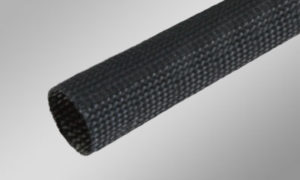

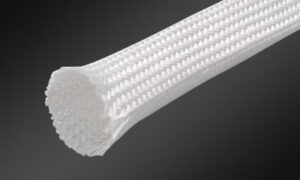

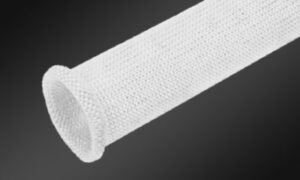

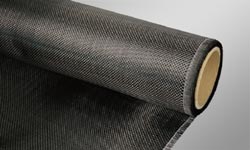

Constructed from non-alkali glass fiber woven tubing coated with high-temperature silicone rubber, our solution provides:

- Continuous thermal resistance: 260°C (EN 45545-2 compliant)

- Instant protection: 1,650°C for 15 seconds (ISO 2685 standard)

- Dual-layer defense: Flame retardancy (IEC 60332) + molten metal splash resistance

Certified Global Compliance

- ISO 9001, IATF 16949

- ISO 2685, IEC 60332, UL 1441

- RoHS, DIN 5510-2 (smoke density <5%)

Operational Benefits

- Worker Protection

Fire Sleeve reduces accessible surface temperatures by 60% (from 800°C to 320°C) - Equipment Reliability

Extends hydraulic hose lifespan from6 monthsto 3+ years in Tesla Giga Press systems - Cost Efficiency

Optimizes annual maintenance expenditure structure per production line

Why Global Leaders Choose Hantai

Our 16-year expertise in Fire Sleeve technology protects critical systems across:

- Automotive

- Aerospace

- Heavy Industry